Supply chains have been changed, possibly forever

The competition is no longer between brands or even between companies; it is between supply chains (networks). Supply chains in the time of coronavirus have changed, possibly forever. MARZIA STORPIOLI reports.

Supply chain management has been likened to a philosophy, a concept rather than an essential service.

Historically, companies relied on strong brands and good products to win over the consumer. Competitive advantage was gained by the organisation based on the strength of its brands and its reputation for quality products.

But as the COVID-19 pandemic continues its inexorable march across the globe, supply chain management is no longer being considered merely a concept, but rather a life-saving essential service used for the cohesion of all supply chains so that they may work in concert with one another in order to satiate the needs and wants of people and businesses at all times, including times of crises.

It’s useful to remember wars have been won and lost by the implementation and control of either effective and efficient supply chain management, or the lack of using it to its full potential, as was experienced during the Napoleonic Wars and World War ll. There is little doubt that the post-COVID-19 world will be decidedly different to life as we knew it prior to this scourge befalling us.

There’s no doubt most nations were caught unprepared by its rapid advance. In South Africa, consumers – like those across the globe – adapted their buying behaviour to “cope with this rapidly evolving situation”, as Nielsen researchers put it.

Retail outlets – supermarkets, pharmacies and wholesalers – were unable to satisfy consumer demand for sanitiser products, demonstrating the inability of supply chains within South Africa, and globally, to respond to a meteoric increase in demand for hand washes and sanitiser products, household and industrial bleaches and surface cleaning solutions driven by the global crisis.

Just-in-time (JIT) and lean manufacturing, once seen as the pinnacle of achievement in supply chain performance, may no longer be effective. They were implemented across most global supply chains in the face of mounting pressure to reduce supply chain costs – the aim being to continually strive for increasing levels of efficiency while reducing costs overall.

Efficient, but not robust

These supply chains are operating on razor-thin margins, so much so that they are no longer robust and unable to respond to ‘shocks’ in the system, and have limited capacity to respond to disruption in their supply chains. They are efficient, but they are not robust.

If the disruption continues, eventually these supply chains will stall – manufacturing will stop due to a lack of raw materials or spare parts.

Today, companies that achieve a sustained competitive advantage (Zara, 3M and Dell) are those who have invested significantly in developing responsive logistics capabilities. They are demand-driven and designed from the customer backwards (rather than from operational capability forward – forecast driven). Their supply chains are agile and responsive to changes in consumer behaviour.

Talking of consumer behaviour, self-preservation reigned ahead of South Africa’s national lockdown as the ‘haves’ stockpiled goods at the expense of the poor, the needy, the aged and the sick.

Imagine if the world did not have an effective and efficiently run supply chain to constantly channel food, fuel and other essentials to replace those that have been exhausted because of this ‘feeding frenzy’. There would be further chaos, indescribable misery, an uncontrolled mortality rate and above all, a world economic recession that would surpass the 1929 financial crash!

With the pandemic spreading to South Africa a few months after the initial outbreak in China, Nielsen was able to research global markets, delivering insights into how retailers are dealing with challenges brought about by coronavirus.

Turning a crisis into an opportunity

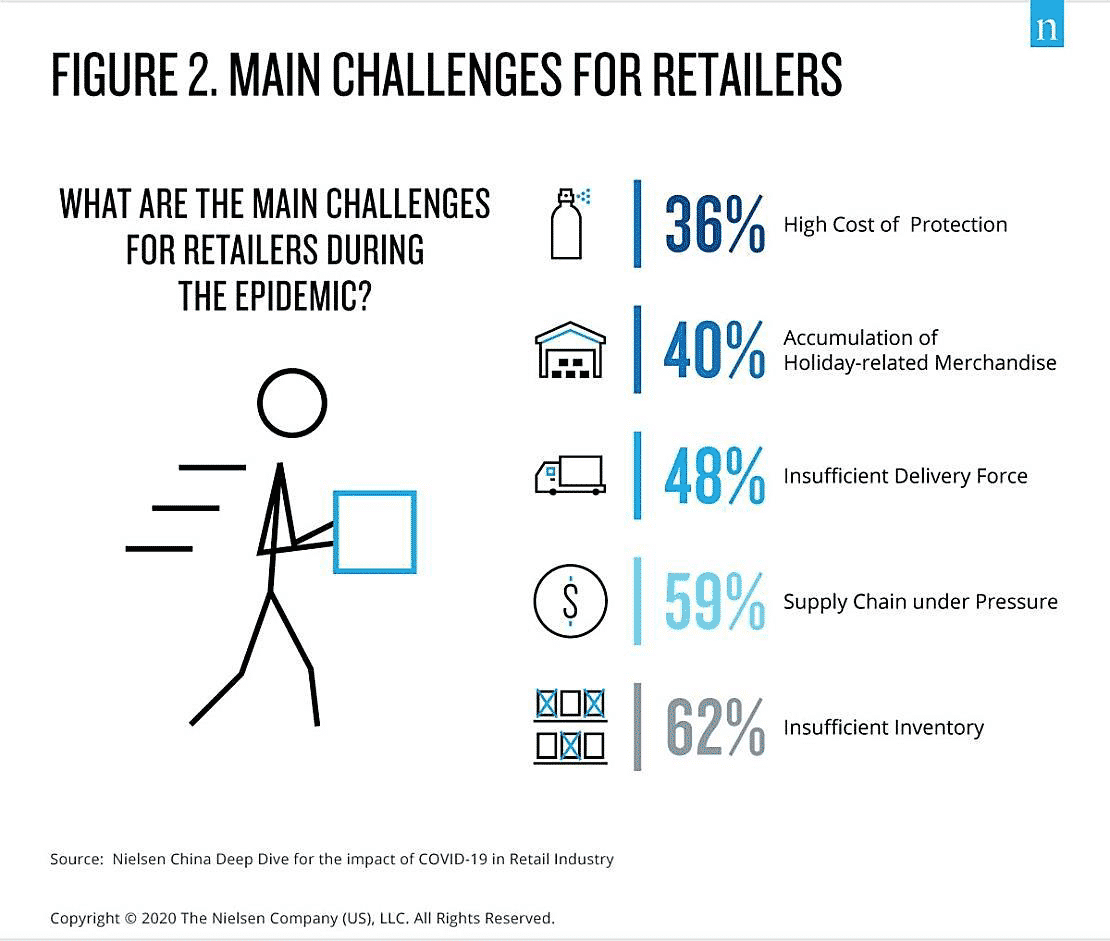

The research shows that retailers are facing three primary challenges: insufficient inventory of some categories, difficulty in logistics and distribution, and inadequate staff to deliver orders.

Those able to organise resources and respond actively to the epidemic and launch measures to “help turn crisis into opportunity” will thrive. These, Nielsen reported, included “flexible co-ordination of participants in the supply chain, ensuring the efficiency of product supply, showing care and concern for employees, rationally deploying staff, adjusting the store’s operating hours, expanding businesses through online channels and in community and strengthening corporate brand marketing to enhance consumers’ trust and creating a favourable impression”.

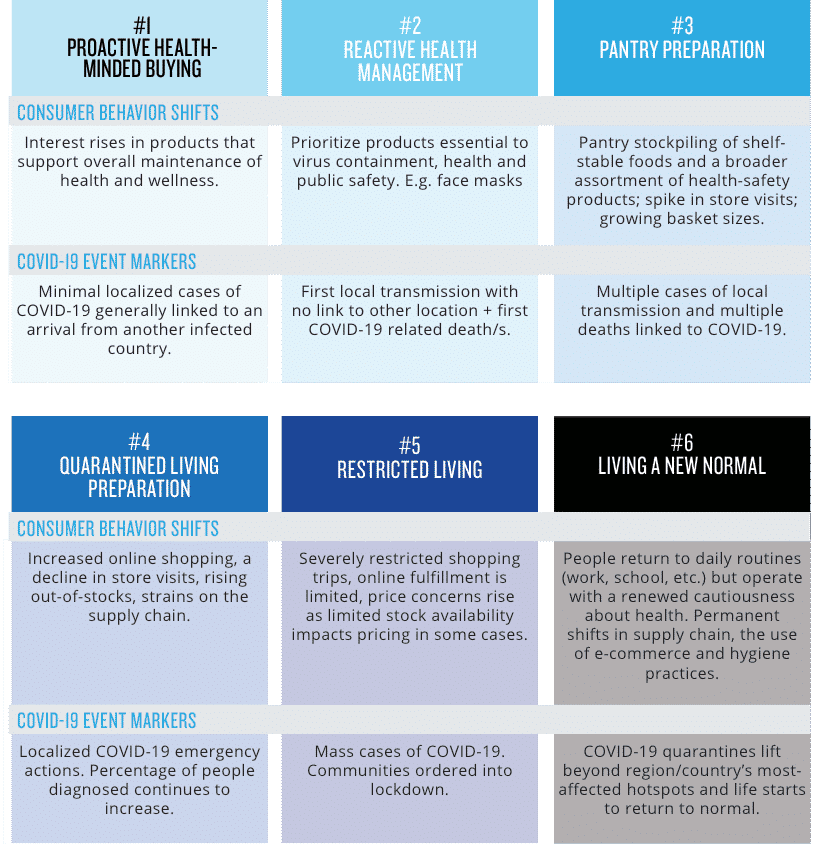

Nielsen has identified six key consumer behaviour threshold levels that tie directly to “concerns around the novel coronavirus outbreak. These thresholds offer signals of spending patterns, particularly for emergency pantry items and health supplies with these patterns being mirrored across multiple markets”.

As African countries such as South Africa and Kenya announced their country-specific responses to the outbreak, Nielsen found that global consumers were adapting their purchase behaviour to cope with the rapidly evolving situation.

“As patterns begin to emerge in response to news events of this nature, it will be imperative for companies to learn from these scenarios so they can sustain growth even in times where COVID-19 is deeply impacting people’s lives. These patterns will help provide leading and trailing indicators to those trying to understand how people will respond as developments continue to play out at different times in different countries,” said Scott McKenzie, Nielsen’s global intelligence leader, adding that this would be critical to understand as stores worked to maintain supply levels of in-demand items.

South Africans entered threshold #5 ‘Restricted Living’ on Friday 27 March 2020. Consumer behaviour at this stage was characterised by severely restricted shopping and constraints due to supply shortages, delivery fulfilment challenges and caps on product quantities, Nielsen reported.

The lessons learned

Of the retailers surveyed by Nielsen on their attitudes towards business for the rest of the year, 67% said they would make efforts to expand online channels and accelerate home-based business / retail warehouse layout.

“Fifty-three [percent] said they would change their product mix according to the shopping habits of consumers and increase the inventory and on-shelf number of health, disinfectant and protection products,” Nielsen reported. “Forty-three percent of the retailers say that they would work on their supply chains, especially those for fresh food, strengthen the ties with various brands and enhance communication efficiency.”

Subscribe to stay informed whenever a new issue is published