A prime imperative: Reinventing supply chains

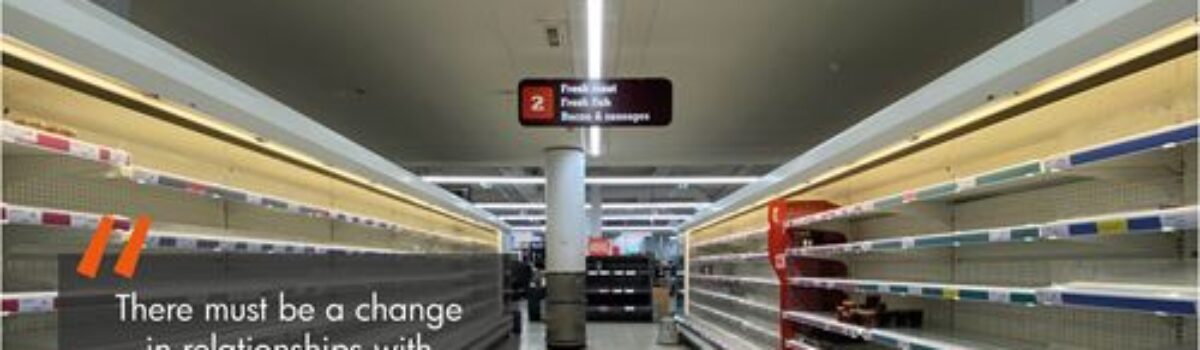

Current disruptions have brought to light the fragility of our supply chains, says MARZIA STORPIOLI. And the volatility is set to continue for quite some time. What to do?

There’s not doubt volatility, turbulence and uncertainty will continue, and probably increase in the decades ahead, and the ‘business as usual mentality’ will need to be replaced with business seeking stability in the face of disruption.

Current disruptions have brought to light the fragility of our supply chains. For the past 20 years, the focus has been on cutting costs along each link in the chain. Unfortunately, this has also expunged any flexibility or resilience (the ability to withstand shocks to the system) in supply chains.

The question now is, how do we retain cost efficiency but reintroduce flexibility and elasticity into supply chains?

Supply chain suppleness – revisited

Just In Time (JIT) has been seen as the model of supply chain superiority, but this is no longer the case. The disruption of supply chains by the coronavirus pandemic showed that this method of inventory control, which brings material into the production process, warehouse or customer just in time to be used, has its limitations.

Some elements of JIT are good and should be translated into the reshaping of the new models for supply chains, but many of the ‘credos’ of JIT will need to be redesigned and new thinking brought into supply chain management.

One of its weaknesses (and other similar methodologies) was that the environmental impact of JIT changes to supply chains was not considered or measured. This is no longer feasible. Consumers are no longer willing to accept ‘due to internal considerations….’ as an excuse for out-of-stock situations.

What will the supply chain of the future look like?

Firstly, the supplier base must be widened to include more suppliers for key/critical items. There should be reduced focus on cost reduction and a move to find a balance between acceptable costs and acceptable inventory levels. This should be done –with customer in mind, rather than the company’s bottom line only.

There should be greater visibility and sharing of information between and among supply chain members e.g. greater trust less ‘protectionism’.

We need to rethink strategies on essential goods and services. For example: chemicals used in sanitiser products – should they be imported because the supplier is cheaper, or should we manufacture the lion’s share in South Africa to reduce reliance on globalised sources?

More joint ventures are required to leverage off each other’s strengths. In other words, we need less outsourcing and more capacity sharing.

A move to on-shoring production of critical items (items critical to national security, health, economic prosperity) is needed.

For example, Sasol has always been able to produce chemicals – world class – why shouldn’t they be incentivised to develop their production to encompass chemicals currently being imported from China (due to some economic cooperation agreement between South Africa and China)?

The South African textile industry has a track record of producing high quality material. Why are we destroying that capacity by importing textile products from China?

Again, South Africa is capable of producing medical quality personal protection equipment. We shouldn’t need to import PPE from abroad.

A trend is developing where businesses collaborate with their competitors, leveraging each other’s unique strengths, buffering their weaknesses and moving closer to becoming ‘demand chains’. This means focusing on customers (outward looking) rather than focusing on internal business efficiencies (inward looking).

There must be a change in relationships with suppliers. It is no longer rational to keep adversarial relationships going, and more important to work on collaborative relationships – the ‘we are in this together’ mindset, as opposed to the traditional ‘beat suppliers down to the lowest price without a thought for their sustainability’.

And that’s just to start with…

BIO: Marzia Storpioli is Lecturer: Supply Chain Management and Programme manager: BCom International Supply Chain Management at the IMM Graduate School.

Subscribe to stay informed whenever a new issue is published